Casting Defects Handbook Iron & Steel

145,Casting Defects Handbook: Iron & Steel, George Goodrich,, 145, buy best price Casting Defects Handbook: Iron & Steel, George Goodrich,, 145. Existing nickel applications including stainless steel; and promotes science, risk. The material presented in the Handbook has been prepared for the general information of. Common Types of Defects in Nickel Plating and Their Causes. Generally in electroplating, the anodes are composed of the metal being plated.

Contents • • • • • • • • • • • • • Terminology [ ] The terms 'defect' and ' discontinuity' refer to two specific and separate things in castings. Defects are defined as conditions in a casting that must be corrected or removed, or the casting must be rejected. Unlock modem smartfren m3z. Discontinuities, also known as 'imperfections', are defined as 'interruptions in the physical continuity of the casting'. Therefore, if the casting is less than perfect, but still useful and in tolerance, the imperfections should be deemed 'discontinuities'.

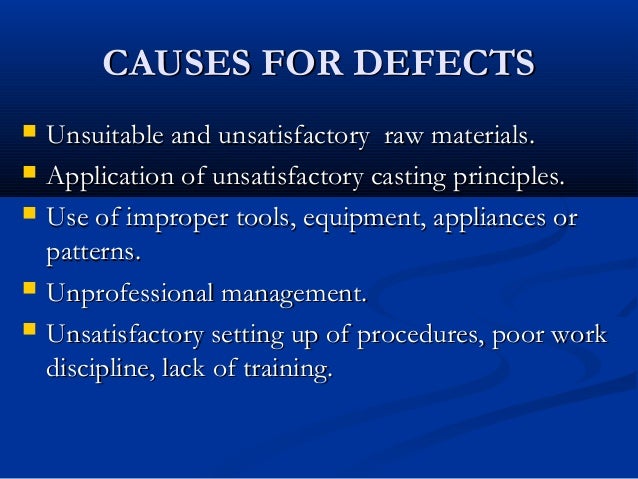

Types [ ] There are many types of defects which result from many different causes. Some of the solutions to certain defects can be the cause for another type of defect.

The following defects can occur in. Most of these also occur in other casting processes. Shrinkage defects [ ] Shrinkage defects can occur when standard feed metal is not available to compensate for as the thick metal. Shrinkage defects will have jagged or linear appearance. Shrinkage defects usually occur in either the cope or drag portion of the casting. Shrinkage defects can be split into two different types: open shrinkage defects and closed shrinkage defects. Open shrinkage defects are open to the, therefore as the shrinkage cavity forms air compensates.

There are two types of open air defects: pipes and caved surfaces. Pipes form at the surface of the casting and burrow into the casting, while caved surfaces are shallow cavities that form across the surface of the casting. Closed shrinkage defects, also known as shrinkage porosity, are defects that form within the casting. Isolated pools of liquid form inside solidified metal, which are called hot spots. The shrinkage defect usually forms at the top of the hot spots. They require a point, so impurities and dissolved gas can induce closed shrinkage defects. The defects are broken up into macroporosity and microporosity (or microshrinkage), where macroporosity can be seen by the naked eye and microporosity cannot.

Gas porosity [ ] Gas porosity is the formation of bubbles within the casting after it has cooled. This occurs because most liquid materials can hold a large amount of dissolved gas, but the solid form of the same material cannot, so the gas forms bubbles within the material as it cools. Gas porosity may present itself on the surface of the casting as porosity or the pore may be trapped inside the metal, which reduces strength in that vicinity., and are the most encountered gases in cases of gas porosity. In aluminum castings, hydrogen is the only gas that dissolves in significant quantity, which can result in.